Cutting

Trident Plastics uses the most advanced cutting equipment available to produce the finest quality cut to size plastic parts in the industry. All of our CNC cutting equipment is calibrated and inspected daily to insure that we deliver precise, close-tolerance cuts. Our Schelling FK6 CNC panel saws can cut sheets as thin as .020” and massive plates up to 8.00” thick with tolerances as close as +/-.005”.

Variable speed controls for blade travel and rotation allow for the perfect cut on a huge variety of different materials including the most abrasive glass-reinforced plastics. Our Behringer Super452 Hydraulic Hacksaw can cut through the toughest materials in sizes up to 18” diameter. Overhead rail saws, table saws and band saws are used for simple oversize cuts and massive shapes up to 10.00” thick.

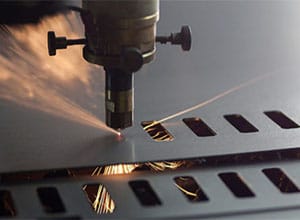

Routing

CNC Routing is an excellent method for producing high volumes of precision cut plastic parts with repeatability, speed and accuracy. Trident can cut complex flat shapes as large as 60”x144” in most materials from .031” up to 2.00” thick using our 3-axis CNC routers which utilize vacuum pumps to hold materials in place while holding tolerances as close as +/-.005”.

Our CNC routers use solid carbide bits to provide a smooth, chip-free routed or milled edge and diamond composite bits can be used to obtain polished edges without the need for a secondary polishing operation. Trident is continuously upgrading its CNC routing capabilities with investments in the latest state of the art machinery. Our machines are equipped with multiple router and drill spindles that can reset their positions on the fly and shuttle between twin tables. Multiple operations can be performed without having to reset the machine or repeat operations. Our CNC routers have the capacity for enormous throughput, making large complex projects, quick, less complicated, and affordable.

Fabrication